Tempered Glass Information

Tempered Glass Information

FABRICATION DEBRIS

Definition:

Fabrication debris is, as the name implies, material that should not be present on glass before it enters or travels thru the tempering furnace. It is made up mostly of glass fines but can include other debris such as insulation particles that have not been properly washed off the glass or cleaned from the furnace rollers. This debris will fuse to the glass surface during the tempering process and create a defective surface that window cleaners and others can dislodge and move across the glass surface in the process of properly cleaning the window.

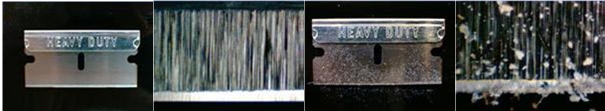

Razor blade before and after use on poor quality tempered glass

Fabrication debris magnified

Window Cleaning Industry

It is well known by window cleaners that razor blades and glass scrapers alone will not scratch uncoated glass when properly used; the use of such tools has been the industry standard for decades. Razor blades and scrapers have been employed by not just the window cleaning industry, but are also widely used throughout the glass industry. In recent years, as a result of contaminated or defective surfaces on some tempered and heat-strengthened glass, window cleaners have been exposed to new challenges and unforeseen liability in window cleaning. When standard window cleaning techniques are employed to clean the contaminated or defective surfaces on poor quality tempered or heat strengthened glass, scratching of the glass surface can and very often does result.

Quality Control in the Glass Industry

Regular annealed glass is tempered or heat strengthened through a specific heating process in order to provide certain safety characteristics. Prior to the heating process, the glass is sized and belt-sanded to the desired edge finish. If the glass is not then properly washed prior to entering the tempering furnace, and if the furnace rollers upon which the glass rides are not kept clean, microscopic glass fines and chips resulting from the sizing and belt sanding will become fused to the surface of the heat-treated glass. These small particles will then cause fine scratches on the surface of the glass when standard construction window cleaning procedures are employed.

The glass washer, furnace and general fabricating plant must be kept in proper working order or poor quality products will result. This is a quality issue when fabricating heat treated glass, not a window cleaning technique issue. Glass scratching, as a result of fabricating debris, has since become a quality, liability and client dissatisfaction issue.

Images of roller marks, low-e coating reaction to fabrication debris, and magnified FD scratches

Builders Education on Quality Heat-Treated Glass

Builders can help resolve this issue by requiring glass and window suppliers to provide only quality heat-treated glass to their projects that can be cleaned using industry standard window cleaning techniques. Builders should only hire qualified window cleaners to remove limited amounts of construction debris from their windows.

Protecting windows during construction is always good practice, but will not protect the future owner from a defective glass product when it does require the window cleaner to use a scraper sometime in the future.

Builders should also recognize the difference between fabricating debris scratches and other types of scratches caused by careless plasters, painters, texture crews and untrained workers attempting to remove construction debris from glass. Fabricating debris scratching is only on heat-treated glass and usually very wide spread, light in nature and mostly visible with direct sunlight. Testing should be done prior to installation. You cannot always detect fabricating debris with these simple tests, but the scratching on the glass it creates is unmistakable. A magnifier can be used to aid in the identification of fabricating debris scratching, with scratches looking like a comet.

Summary and Conclusion

While it may be possible to locate fabricating debris on some heat-treated glass, window cleaners should not accept responsibility for identifying fabricating debris or its’ absence. For this reason, window cleaners should always require a liability waiver, signed by the builder, releasing the window cleaner from any liability for scratching on any tempered or heat-strengthened glass. Builders would also benefit if they required their glass and window suppliers to sign a liability waiver, prior to entering into a contract, to help ensure the builder will get the quality product he’s purchased.

For additional information:

www.stopscratchedglass.com

http://sites.google.com/a/windowcleaningresource.com/www/fabricatingdebris

www.iwca.org

How can Innovative Window Cleaning help you? Contact us TODAY to find out

Navigation

Our Chicago Location

INNOVATIVE WINDOW CLEANING

2215 Gray Hawk Dr

Plainfield, IL. 60586

info@innovativewindowcleaning.

1 (888) 535-1440

Our Tampa Location

INNOVATIVE WINDOW CLEANING

3285 Acacia Bay Ave

Wesley Chapel, FL. 33343

info@innovativewindowcleaning.

1 (888) 535-1440